Titanium (Ti) – a brief history of the origins and commercial applications of titanium

Titanium is a chemical element (Ti) – atomic number 22 – and it has an atomic weight of 47.867. On the periodic table, titanium sits between manganese and cobalt, possessing a beautiful pale silver color.

Titanium is a lustrous silver metal with the highest strength-to-density ratio of any metallic element. Photograph by Alchemist-hp

The discovery of titanium

Titanium was discovered in the year 1791 by the Reverend William Gregor in the county of Cornwall, south-west Britain.

On a walk one day, Reverend Gregor, while crossing a small stream, noticed a layer of black, magnetic sand. The sand resembled gunpowder in appearance. The name we use for this sand today is ilmenite – an ore consisting mainly of iron oxide and titanium.

Part of the sample he took was a reddish-brown color. He could see an oxide in the sample and knew it was a new metal but could not isolate it. He named the new metal – ‘manaccanite’ – in honour of the parish of Manaccan where he lived.

Titanium

A few years later in 1795, the German chemist Martin Klaproth discovered what he thought was a new metallic element. Klaproth called his new metal – ‘titanium’ – after the Titans from ancient Greek mythology.

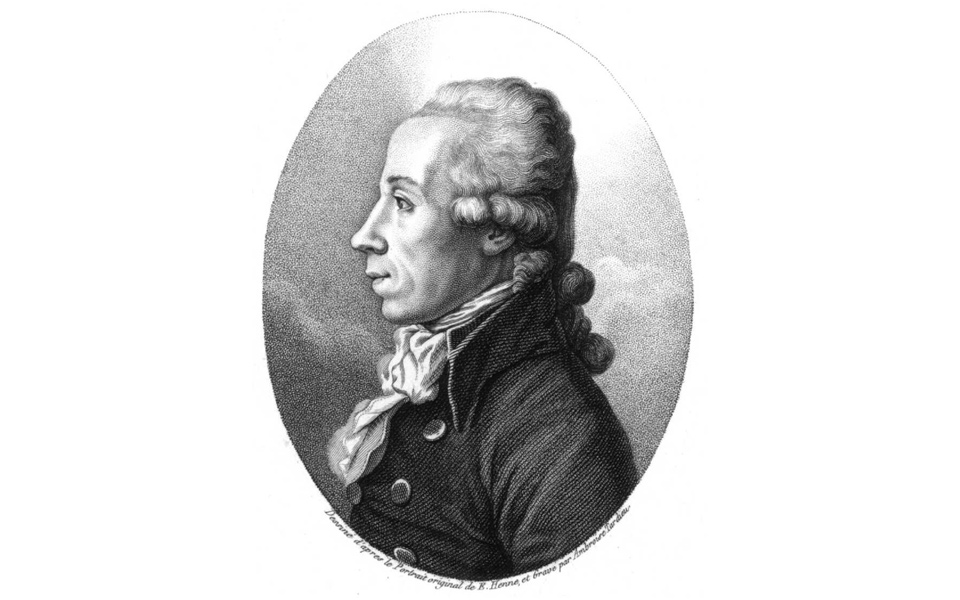

Engraving of German chemist Martin Klaproth 1743 – 1817, the discoverer of titanium, by Ambroise Tardieu after an original portrait by Eberhard-Siegfried Henne.

Klaproth had discovered titanium in rutile minerals from a deposit in Boinik, Hungary. In 1797, Klaproth had the opportunity to read Gregor’s account of his discovery in 1791, and Klaproth then realised that the red oxide in which he had found his titanium and the red oxide in which Gregor had found manaccanite were identical. Titanium and manaccanite were the same elements, and Gregor was given the recognition as the element’s true discoverer.

However, the name titanium was thought to be more fitting, and that was the name adopted by science.

Purifying titanium

It was more than a century after titanium’s discovery, that scientists and engineers found a way to produce a 99.9% pure sample of the element.

It was eventually isolated in 1910 by the metallurgist Matthew Hunter in Schenectady, a small town on the east side of the United States. His process included heating titanium (IV) chloride with sodium to a red hot heat in a pressure cylinder.

It took another 30 years until the commercially viable process, the Kroll Process, was invented by William J. Kroll in Luxembourg. Kroll’s method worked by heating titanium (IV) chloride with magnesium and made the commercial production of titanium possible. At the time, only tiny amounts of the metal were produced, and even in 1948, the worldwide production of titanium was only 3 tons a year.

Demand for the metal continued to grow, and by 1956 global production of titanium reached 25,000 tons per annum. Today we produce well over 250,000 tons per year.

Commercial uses

Titanium is a strong, durable and lightweight metal that is in extremely high demand by many industries. For instance, a Boeing 777 has a maximum, empty, operating weight of approximately 304000 lbs or 137.8 metric tonnes. Of that enormous weight, 59 metric tonnes is constructed from titanium.

The Boeing 777 is constructed using 59 tonnes of titanium and about two thirds of all titanium metal produced is used in aircraft engines and frames.

Its superior strength and light weight relative to other metals (steel, stainless steel, and aluminium), means titanium is used in many sporting goods such as tennis rackets, golf clubs and bicycle frames. For the same reasons, it is also used in the body of high-end laptop computers like the Apple PowerBook.

The metal is soluble in concentrated acids but not water. If you were to submerge a sheet of titanium in seawater for 4000 years, it would only have corrosion to the depth of about the thickness of a piece of copier paper. This remarkable resistance against corrosion makes titanium the perfect metal to create the hulls of submarines.

Titanium is resistant to corrosion by seawater and is used in the housings and components of ocean-deployed surveillance and monitoring devices for science and the military.

Titanium also has a significant role as an alloying agent. It is commonly smelted with other metals including aluminium, manganese, iron and some grades of stainless steel to improve their ability to be welded.

For us at Double Stone Steel, titanium is a vital part of our PVD process. Without titanium, Double Stone Steel would not have a business!

Many of Double Stone Steel’s PVD colored stainless steel sheets and profiles are colored using a charged ion plasma gas, consisting of a mix of titanium and other metals.